减少生猪运输风险的生物安全经验和措施

来源:猪译馆 2020-03-25 13:45:03| 查看:次

译者的话:<<

随着行业对疾病爆发的不断了解和深入调查,各个体系的生物安全规定也在不断改进。生物安全规定旨在降低疾病传播的风险,但当这些规定在大型生产体系中执行时,并没有一种既经济又适用于所有体系的方式。

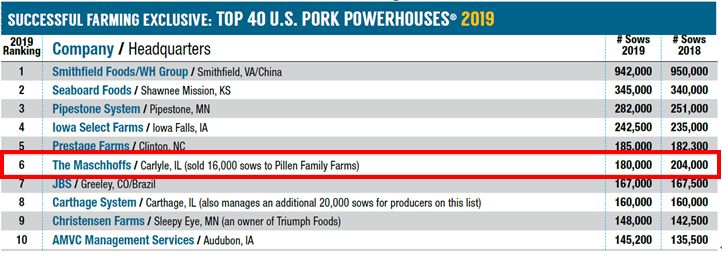

本文介绍了美国排名第6的养猪企业马绍夫集团,在减少活猪运输风险方面的生物安全经验和措施。马绍夫集团在2019年初拥有19.6万头母猪,全球排名第15,全美排名第5(2019年中出售了1.6万头母猪,现存栏母猪18万头,全美排名第6)。

减少生猪运输风险的生物安全经验和措施 - AASV 2020

Biosecurity lessons learned and action steps to reduce the risks associated with live animal transport - AASV 2020

介绍Introduction<<

作者 Authors:

A. Maschhoff, DVM

M. Hensch, DVM

S. Stehlik, DVM

J. Miller DVM马绍夫集团,伊利诺伊州卡莱尔市

The Maschhoffs, LLC, Carlyle, Illinois

介绍Introduction

随着行业对疾病爆发的不断了解和深入调查,各个体系的生物安全规定也在不断改进。生物安全规定旨在降低疾病传播的风险,但当这些规定在大型生产体系中执行时,并没有一种既经济又适用于所有体系的方式。过去几年中,在马绍夫体系 (TML)内的疾病爆发调查揭示了运输生物安全方面的差距,这些差距包括拖车的卫生、司机的规定和猪场间的关联。因此,马绍夫体系采取了各种措施来减少活猪运输相关的风险。

As the industry continues to understand and investigate disease outbreaks, continual improvement of biosecurity protocols take place system to system. Biosecurity protocols are designed to reduce the risk of disease transmission, but when those protocols are in practice within a large production system, there is not a one-size fits all approach to mitigating disease entry in a cost-efficient manner. Over the past several years, disease outbreak investigations within The Maschhoff system (TML) revealed gaps within transport biosecurity. Those gaps included trailer sanitation, driver protocols and connections between sites. Therefore, TML has implemented a variety of protocols to reduce risks associated with live animal transport.

这些措施围绕卫生、隔离、专用和审计执行这些方面。下列措施已在商品场和种猪场广泛采用。

Those actions steps center around the concepts of hygiene, segregation, dedication and audited execution. The following action steps have been variously applied between the commercial and genetics operating regions.

清洁和消毒 Hygiene and sanitation<<

正如许多体系所描述的那样,马绍夫体系一如既往地对拖车进行清洗和消毒。马绍夫体系用标准的操作流程(sop)来制定要求,并持续通过内部审计和第三方审计来确保达到要求。在马绍夫体系内大多数公司自有的卡车清洗站都使用热辅助干燥和消毒(TADD)。在过去一年内,马绍夫体系为那些在到达第一个装猪点前行驶了很长一段路程的拖车,在额外的地方增加了专用的热辅助干燥和消毒系统。在这些加热干燥和净化装置中,用温度指示贴来监控拖车是否达到所需的温度。除了拖车本身,马绍夫体系还有一整套在猪场间转猪时需执行的清洁和消毒规定,例如对赶猪板、司机的水鞋和服装的要求。马绍夫体系也为卡车(注:美国生猪运输中,卡车Truck特指牵引拖车的车头,与拖拉机/牵引车的作用一样)卫生制定了标准操作流程,在卡车清洗站准备了工业吸尘器和清洁设备。司机在送回一辆用过的拖车,结束一天的工作前,需要清洁驾驶室,要拿走垃圾,用吸尘器清理,并用消毒剂擦拭驾驶室内部的表面。之后卡车清洗站员工对卡车的外部和内部的脚垫进行清洗和消毒,最后将卡车停放在卡车清洗站的“净区”。

As has been described by many systems, The Maschhoffs continue to implement both wash and disinfection protocols to clean trailers. TML has standard operating procedures (SOPs) that define the expectation and utilize continual internal and 3rdparty auditing to ensure those SOPs are met within the system expectations. TML has actively utilized Thermo-Assisted Drying and Decontamination (TADD) at most company owned truck washes. Within the past year, the system added additional locations with dedicated TADD systems for trailers that travel a significant distance prior to reaching their first loading site. Within those TADD systems, the system utilizes temperature tracking stickers to monitor that trailers are reaching desired temperatures. Outside of the trailer itself, the system has integrated hygiene and sanitation protocols for the supplies utilized when moving pigs from site to site, such as expectations for sort boards, driver boots and clothing. TML also created SOPs for truck hygiene as well, making industrial vacuums and cleaning supplies readily available at truck wash locations. When the drivers drop off a used trailer, they are required to clean the interior of their cabs by removing trash, vacuuming out the cab, wiping down interior surfaces with disinfectant wipes prior to ending their day. The truck wash staff then washes and disinfects the exterior of the truck and interior floor mats prior to moving the truck to the “clean” side of the truck wash.

隔离 Segregation<<

卡车清洗站分区 Segregated truck washes

马绍夫体系在多个方面实施了隔离措施。首先,也是最重要的,该系统致力于建立一个专用于部分核心场和扩繁场的分区式卡车清洗站。这可降低这些猪群的风险,除了向商品场提供后备猪外,可将这些猪场与商品场分隔开。这个隔离的卡车清洗站包括隔离的拖车、卡车、司机和设备。在猪场地理位置无法实行隔离的情况下,会对共用一个卡车清洗站的商品场进行更多的传染病检测。此外,马绍夫体系还与第三方签约生猪运输商建立了独特的关系,将该体系的卡车和拖车与其他生产商隔离开。通过这两项隔离措施,马绍夫体系能够更快速地控制和调整猪场间的风险,因为当传染病发生时,可在内部供应链中进行调整。在马绍夫体系的自有卡车清洗站内,还设立了一道脏净区分界线,防止司机在送回使用过的卡车和拖车时,接触到清洁的卡车和拖车。

TML has approached segregation through multiple facets. First and foremost, the system committed to building a segregated truck wash that was dedicated to a portion of the nucleus and multiplier herds. This allowed for mitigating risk within those herds and separating them from commercial farms except in the case of delivering replacement breeding stock to commercial farms. This segregated truck wash includes segregated trailers, trucks, drivers and equipment. In situations where segregation was not feasible based on geography of sites, additional epidemic disease testing has been implemented at commercial sites that share a common truck wash. Additionally, the system has developed exclusive relationships with third party live haul contract systems to provide segregation of TML trucks and trailers from other producers. In both of these segregation steps, TML has been able to more rapidly control and adjust for risk between sites because when epidemic disease strikes adjustments can made within the internal supply chain. Within TML owned truck washes, clean dirty lines are also established to control driver footpaths at the beginning and end of day, keeping drivers fromcontacting clean trailers and trucks when they return to drop off used trucks and trailers.

拖车等级系统 Trailer classification system

为进一步区分拖车和卡车,马绍夫体系使用了一套等级系统对拖车进行区分。这套等级系统清楚地描述了拖车和卡车可从哪里开始,可将猪运送到什么类型的猪场,并描述了等级对应猪场的健康要求。例如,一个猪场对于等级定义的传染病,如PRRSV(猪繁殖与呼吸综合征病毒)转为阳性了,该猪场将从高等级中移除,并移到一个低的等级。同时还描述了不同拖车等级对清洗、消毒、加热干燥和消毒程序,以及隔离时间的具体要求,以便体系能够将生物安全和拖车的使用效率进行平衡。这些标准操作流程和隔离时间适用于司机、卡车和拖车。在未来,该系统计划将拖车和卡车的等级通过外部标记进行标识,并且可以很容易进行识别,这将方便员工在装运或接收猪群时,进行最终的检查和等级确认。

To further segregate trailers and trucks, TML has implemented segregation of trailers through a classification system. That classification system clearly outlines where the trailer and truck can start, what site type the trailer and track can deliver animals too and outlines specific health designations within that class. For example, if a site is positive for a system defined epidemic disease, such as PRRSV, that site would be removed from high level classifications and moved to a lower tier. Specific requirements are then defined for wash, disinfection, TADD procedures and downtime between those trailer classes, so that the system can still balance biosecurity and utilization of system available trailer capacity. Those SOPs and downtimes apply to the driver, truck and trailer. In the future, the system plans to implement a program where the trailer and truck class are easily identified through exterior markings, which will allow for final inspection and confirmation of class by the team at the shipping or receiving herd.

淘汰猪中转站 Cull transfer chutes

隔离的第二项措施是建立淘汰猪中转站。这些中转站可将母猪场和与淘汰猪收购站接触的拖车隔离开。将淘汰母猪装运在特定的母猪场专用拖车或特定等级的拖车上,从母猪场运输到中转站。在中转站,用签约承包商拖车或体系自有的低等级拖车将母猪运输到另一辆拖车上,最后将母猪运输到淘汰猪收购站。这项措施在没有增加一系列生物安全规定的情况下,如额外的清洗或隔离时间,减少了拖车与母猪场和淘汰猪收购站的接触。这项措施已在种猪场和商品场采用。

The second step in segregation was through the implementation of cull transfer chutes. These transfer chutes are utilized to segregate trailers contacting sow farms from cull buying stations. Cull sows are loaded on specific sow farm dedicated trailers or within a specific classification of trailers and then moved from the breeding farm to the transfer chute. At the transfer chute, a contract hauler or internal trailer of a lower classification moves the sows to a different trailer and hauls them to the cull buying station. This step mitigates trailers from contacting sow farms and cull buying stations without an increased series of biosecurity steps such as additional washes or downtime. This process has been implemented in both genetic and commercial assets.

司机的隔离 Driver segregation

根据内部的调查,马绍夫体系额外采取了一些措施,将运输生猪的司机进行隔离,以减少司机在装载或卸载猪时与猪场的接触。这是通过不同的猪场使用不同的措施来执行的,如分段装猪,或由猪场的员工装载或卸载拖车。这样既可让司机留在驾驶室内,又可防止司机与猪进行额外的接触。这两项措施都需要对传统的标准操作流程进行一些改变,并且需要对母猪场进行资金和人员的投入,以便猪场员工将猪装载或卸载到拖车上。这些措施包括,但不限于,要求猪场员工在装载后重新进猪舍前进行多次淋浴,其中一次淋浴是在被指定为“脏”的淋浴间,另一次淋浴是在正常进猪舍的淋浴间。这一措施也使装载猪时员工穿的衣服隔离在猪场的“脏区”,并在下一次使用前进行清洁和消毒。

Due to some internal investigations, TML additionally has taken steps to segregate live haul drivers from contacting the sites during pick up or delivery of animals. This has been implemented through a variety of site-specific steps, such as staged loading rooms or unloading the trailers by the farm staff – both leaving the driver in the cab and preventing additional pig contact with the live haul driver. Both those mitigation steps require a series of additional changes to the traditional SOPs and investment in capital and labor on the sow farm to allow for the farm staff or load or unload pigs onto a trailer. Those steps include, but are not limited to, asking the farm staff to take additional showers prior to re-entering the unit, one of those shower locations being designated as a “dirty” shower and one through the normal site entry shower. This mechanism also keeps the loading clothing separate on the “dirty” side of the farm and requires cleaning and disinfection prior to use again on the next load of pigs.

专用 Dedication<<

一个体系不仅需要清洁干燥的拖车和隔离的标准操作流程来改善生物安全,还需通过专用来降低风险。在一些猪场上,马绍夫体系投资了专用的拖车。这些专用拖车只运输一个或一些特定的场。虽然这会增加成本,但在一些情况下,“保险”费用被认为是对这些特定猪场的良好投资。

Not only does a system need clean, dry trailers and segregation SOPs that support increased biosecurity, but dedication can also play a role in mitigating risks. For a few sites TML has invested in dedicated trailers. Those dedicated trailers only haul for a specific site or set of sites. Though this comes at an added cost, in a few situations the “insurance” cost was determined to be a good investment towards protecting those specific sites.

结论Conclusion<<

虽然以上列出的这些示例措施对减少疾病进入不是万无一失的,但他们是从马绍夫体系的疾病爆发中获得的经验教训,且这些措施目前正在对应的最经济有效的区域内采用。与大多数生物安全规定一样,这些也可能会发生人为错误,但随着更多关于有效降低疾病风险措施的研究的出现,应继续对这些措施进行评估和采用,以减少代价昂贵的传染病的爆发。

While these example action steps listed above are not foolproof in mitigating disease entry, they are applications of lessons learned from disease breaks with The Maschhoffs and are currently being applied today within the region(s) where those actions are most cost efficient and effective. As with most biosecurity protocols, human error is likely to occur, but as more research about effective mitigation steps becomes available, those steps should be continued to be evaluated and utilized to reduce costly epidemic disease breaks.

温馨提示<<

1、本文由猪译馆猪译官钱金花翻译,猪译馆有中文版权,如需转载,请联系我们。

服务热线:400-808-6188

Copyright©2010-2022 https://www.zhuwang.cc